Creating a safe and healthy workplace doesn’t happen by chance—it’s the result of deliberate planning, proactive strategies and a company-wide commitment to preventing harm before it happens.

According to the Occupational Safety and Health Administration (OSHA) the primary goal of a safety and health program is to prevent workplace injuries, illnesses and deaths as well as the suffering and financial hardships these events can cause for workers, their families and employers.

Historically, approaches to jobsite safety have been somewhat reactive; that is, addressing problems only after a worker sustains injury or once a new regulation or standard is published. Although with ever-evolving jobsites, proactive approaches have become far more effective in achieving safety and health program goals.

The key tenets to an effective and proactive safety and health program include a strong safety culture, jobsite analysis, hazard prevention/mitigation and appropriate training. These elements are essential for managing safety across a variety of jobsites and dynamic work environments.

A strong safety culture requires buy-in from both management and employees. Everyone must be involved in identifying hazards, reporting conditions and contributing to solutions. This requires open communication between employees and management. The employer’s role extends beyond simply providing resources—they must also establish the practices and procedures for safety programs and ensure compliance. An essential practice is jobsite analysis.

Jobsite analysis involves the identification of potential hazards, assessing their severity and implementing controls to mitigate their risk. Implementing a jobsite analysis (JSA) is a key step to protecting your employees, the public and the environment from hazards that may arise. For project sites with various scopes and dynamic operations, a JSA is a primary measure for risk mitigation. Jobsites may be remote, heavily vegetated or in a dense urban setting. Understanding the hazards that each type of site may present in combination with utilization of control measures, appropriate training, and good practices and policies help to mitigate risk.

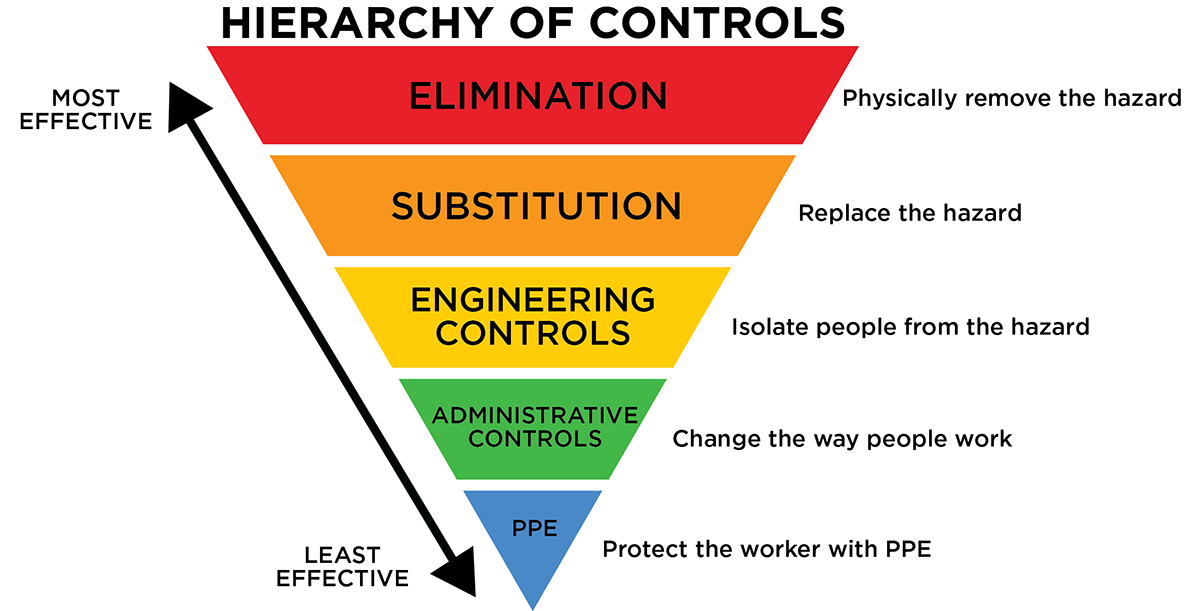

Some of the most basic practices that all employees can contribute include good housekeeping of work areas. These practices are applicable to all jobsites and to our personal lives. Further, all employees must be on the lookout for hazards. When a hazard has been identified, a hierarchy of control options should be considered.

The most effective control option is to remove the hazard. Can the hazard be physically removed from the site or eliminated from the process?

If elimination isn’t feasible, consider substitution: Can the hazard be replaced with something less hazardous? Is there an alternative, less hazardous process that can be utilized?

In many situations, some hazards will remain. Engineering controls reduce exposure by preventing hazards from coming into contact with workers. Is there a way or are there devices to isolate workers from the hazard? Some examples of engineering controls include noise enclosures, ventilation systems and machine guards.

Even still, risk from a hazard may exist. Administrative controls change the way work is done or give workers more information. Are there procedures that can be put in place to mitigate this risk? What training does a worker need to perform their job around this hazard? Are there appropriate warning measures in place to inform the worker? Administrative controls may include procedures and training specific to the hazard. Additionally, administrative controls include signage, detection and alarm systems, and messaging systems to properly inform the worker about the hazard.

Finally, the most basic control method is personal protective equipment (PPE). PPE can vary from hazard to hazard and therefore from jobsite to jobsite. Types of PPE may include safety glasses, protective clothing, hardhats, hearing protection, personal fall protection and respirators. Not all types of PPE are appropriate and effective for all jobsites and all hazards.

Remember, the first step is to identify the hazard. This step requires participation from all workers! Then brainstorm how the hazard can be eliminated, substituted, engineered out, administratively controlled, or what PPE can be used with other controls. At the heart of it all is participation. This approach is most effective when there is a joint effort from workers and management, grounded in open communication and shared accountability.

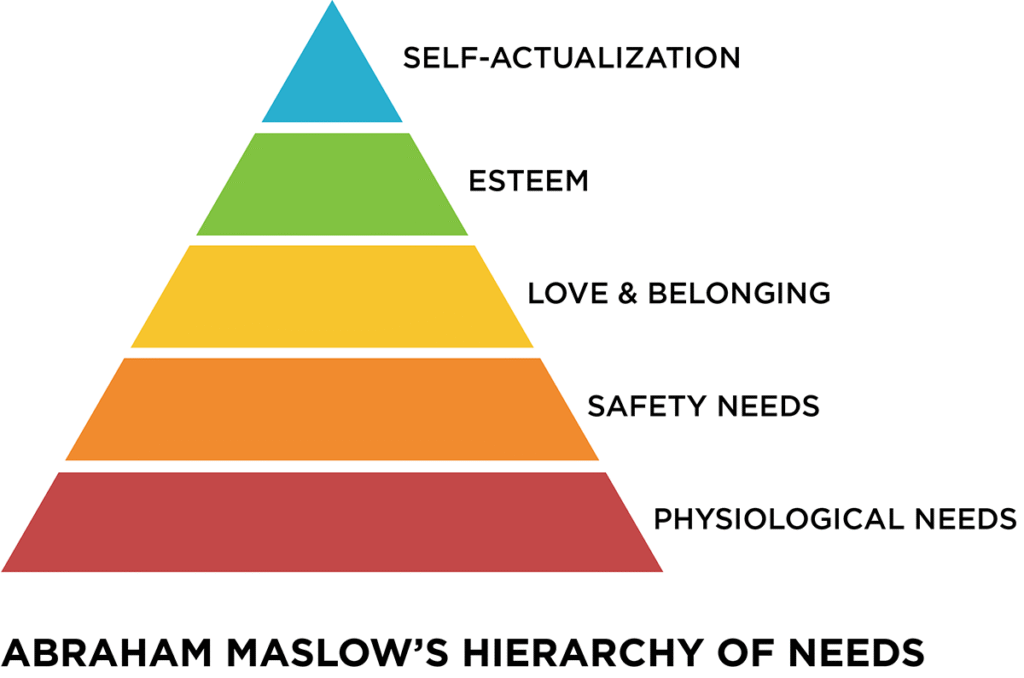

When supported by thorough jobsite analysis, effective hazard mitigation and targeted training, a strong safety culture does more than reduce accidents. It promotes employee well-being, increases productivity and strengthens the organization’s reputation. Ultimately, safety is not just a set of rules. It is a shared mindset that empowers every worker to thrive in a secure, confident and high-performing environment.